FaceForm

An industrial design project focused on creating a face shield that provided all-around protection for frontline workers during the peak of the COVID-19 pandemic.

Problem Statement

In April 2020, as the world came to a standstill, strict lockdowns were enforced across densely populated Indian cities to slow the rapid spread of COVID-19. During this period, frontline workers continued their essential duties—often with limited access to proper protective equipment or relying on substandard alternatives. As infection rates rose, hospitals became overwhelmed, and fear among healthcare workers intensified, the need for reliable, comfortable PPE became increasingly urgent.

In response, the Pune Municipal Corporation opened tenders to individuals and organizations for the supply of protective gear, including PPE kits and face shields. This prompted the team to investigate the limitations of face shields being used at the time. Through this research, they identified key issues and set out to design practical, ergonomic, and effective face shields suitable for extended use. The challenge was clear: develop a solution that could be produced quickly and deployed immediately to meet the demands of the crisis.

Project Brief

How might we rapidly and effectively reduce the physical and emotional strain on frontline workers during the COVID-19 pandemic?

Research & Key Takeaways

We conducted a focused 15-day research process to understand challenges frontline workers faced with existing face shields, interviewing 15+ professionals, including doctors, nurses, via video calls and sanitation workers, in socially distanced meetings. Due to the lockdown in India, market research relied on online ethnography, where we analysed e-commerce platforms and social media to identify and purchase commonly used shields, assessing design limitations and user pain points.

Our interviews with frontline workers focused on five key themes, revealing the following insights:

Comfort: Many shields were too tight, caused pressure points, or slipped during long shifts.

Clarity & Visibility: Low-quality plastics distorted vision, fogged up easily, and led to eye fatigue.

Compatibility: Shields often interfered with glasses, KN95 masks, and surgical headlights.

Usability: Many designs were hard to wear, difficult to clean, and left the bottom of the face exposed.

Availability: Hospitals often received bulk, low-cost shields that were flimsy and broke easily. Some face shield holders arrived broken at hospitals.

Conducted agile research with 15+ interviews with frontline workers and online ethnography to understand challenges with existing face shields.

Purchased and analyzed commonly used shields to identify design flaws and user pain points.

Design Inspiration & Manufacturing

While we conducted our research and interviews with frontline workers, we also explored fast and cost-effective manufacturing methods to bring our face shield designs to life. This led us to take inspiration from two widely used packaging products.

The first was the thermoformed punnet box, commonly used for fruits and vegetables. Its clear, lightweight structure and affordable production process made it a practical reference for our FaceForm shield

Prototyping

Based on the findings from our research, we developed a set of design principles, which formed the iterative prototyping phase. These principles are as follows:

Comprehensive Protection: Provided full-face coverage, forehead to chin, ear to ear.

Comfort & Ergonomics: Priority for use during long shifts

Must fit with existing PPE (masks, goggles, headbands)

Zero distortion: Optical clarity is Priority.

Modular & Scalable Production: Reduced part count to speed up assembly and reduce failure points.

Ease of Use & Distribution: Ease of use under pressure, storage and transportation.

Durability > disposability for supply-constrained hospitals.

Phase 1:

Initial Design & Fit

The first phase of prototyping focused on developing a face shield with full coverage—from forehead to chin and ear to ear—while ensuring comfort by minimizing pressure points. The design balanced user needs with manufacturing constraints to enable efficient production. A wooden mold was used for thermoforming, allowing quick iterations. Initial testing revealed ergonomic and sizing issues, leading to further refinements for improved fit and usability.

Phase 2:

Ergonomics & Attachment

The second phase concentrated on enhancing fit, ergonomics, and scalable manufacturing, while simultaneously exploring branding and attachment methods to ensure the shield stayed secure and comfortable. Multiple options, such as elastic bands and snap-fit buckles, were tested for comfort, adjustability, and usability. Following user testing and iterations, a drawstring system with an elastic cord and toggle lock was finalized, providing easy fit adjustment and stability.

Pre-Production Phase:

Optical Clarity & Refinement

In the pre-production phase, the focus shifted to improving visual quality and user experience, with frontline workers stressing the need for high optical clarity and zero distortion for precise medical tasks. Collaborating with the manufacturing team, multiple sample batches were produced and tested, adjusting material handling and forming parameters. Rigorous fine-tuning resulted in a final product that provided clear, undistorted visibility and comfort for extended use in demanding conditions.

The initial design focused on full-face cover, comfort, and manufacturing feasibility.

Improved fit, ergonomics, manufacturing scalability, & finalized a toggle-lock drawstring for comfort fit.

Focused on optimizing materials and manufacturing to enhance visual clarity, eliminate distortion, & improve comfort.

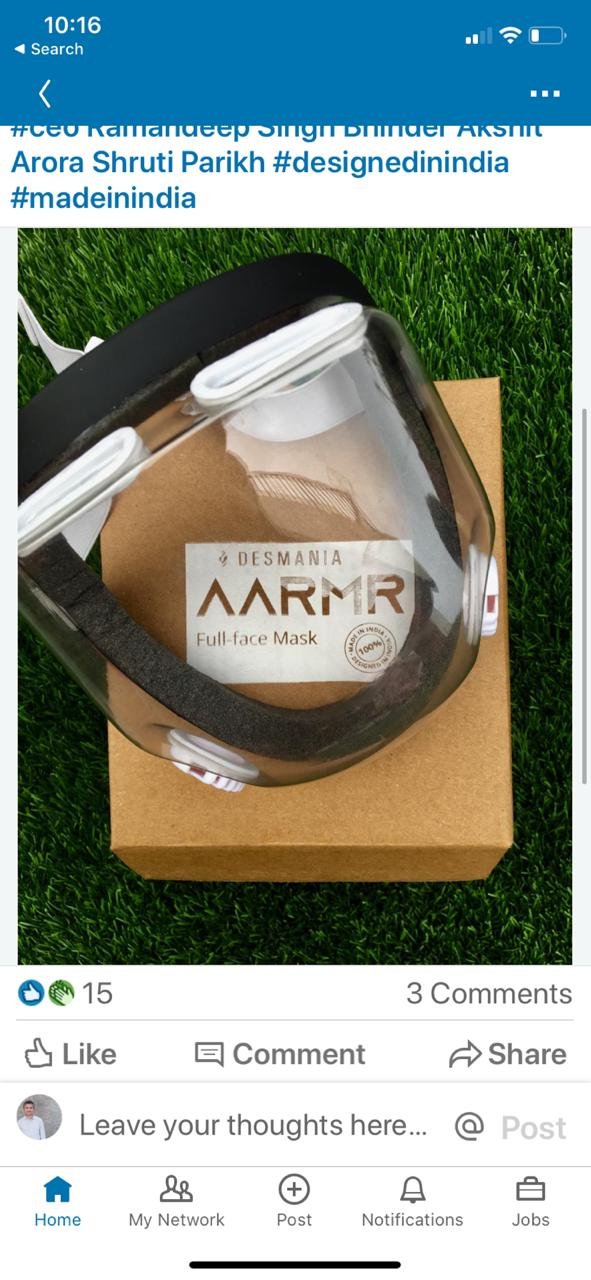

FaceForm

Final Concept

FaceForm is a lightweight, ergonomically designed face shield created to address COVID-19. It is designed to provide full-face coverage while accommodating masks and glasses. Made from 0.4mm thermoformed PET, it offers optical clarity, durability, and comfort with reduced pressure points. The design is optimized for cost-effective manufacturing, easy assembly, bulk distribution, and optional branding.

Manufacturing

During the design phase, we partnered with a Pune-based thermoformed box manufacturer to enable fast, iterative prototyping and refine the face shield for frontline workers. Alongside development, we sourced key components like elastic cords, toggle locks, and custom branding stickers. By early June 2020, after multiple rounds of testing, we finalized the design and launched a 500-unit pilot run, followed by a second batch of 5,000 units for large-scale distribution. This approach ensured a rapid response to urgent COVID-19 demand while maintaining quality and consistency. View images from the manufacturing phase below.

Rapid Development: Partnered with a Pune manufacturer and used an agile process to quickly prototype and refine the face shield.

Pilot Manufacturing: Sourced key components and manufactured a 500-unit pilot batch in early June 2020.

Scaled Manufacturing: Produced 5,000 units for distribution, ensuring speed, quality, and consistency by the end of June 2020.

Implementation & Feedback

In June 2020, we were awarded a tender to supply face shields to the Pune Municipal Corporation, leading to the deployment of over 5,000 FaceForm units across departments such as emergency care, sanitation, hospitals, and police by July. Alongside fulfilling the tender, we sold over 200 units independently and donated another 200 to charitable organizations supporting COVID-19 efforts. Feedback from healthcare workers was largely positive, highlighting comfort, visibility, and compatibility with existing PPE, though some noted minor fogging in outdoor settings. The project underscored how simple, user-focused design, supported by local manufacturing and efficient distribution, can play a vital role in crisis response.

Tender Awarded: Supplied 5,000 FaceForm shields to Pune Muncipla Corporation by July 2020.

Wider Reach: Sold 200+ units and donated 200 to COVID-19 relief efforts.

User Feedback: Received positive feedback for comfort, visibility, and PPE fit; with minor fogging noted in outdoor settings.

Design Impact: Demonstrated value of user-focused, locally sourced and made, scalable solutions.

View more case studies.